重量轻

Lightweight

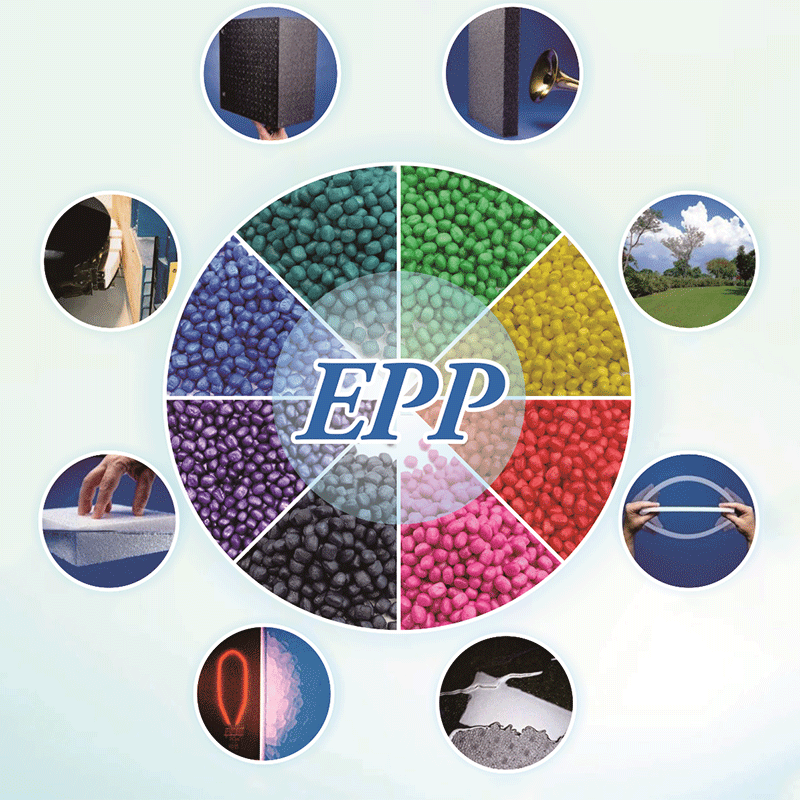

EPP是以聚丙烯为连续相,气体为分散相的聚丙烯/气体两相复合材料。可通过气体改变聚合物相的形态、结构,使之具有质轻、优异的力学性能、耐热、回弹性优等特性。

EPP is a polypropylene/gas two-phase composite material with polypropylene as the continuous phase and gas as the dispersed phase. The morphology and structure of polymer phases can be altered by gas, resulting in lightweight, excellent mechanical properties, heat resistance, and superior resilience.

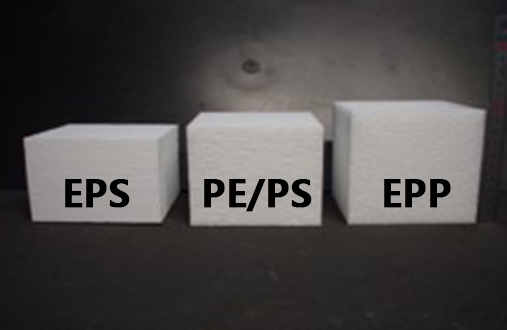

| 项目 Project |

发泡聚丙烯 EPP |

发泡聚乙烯 EPE |

发泡聚苯乙烯 EPS |

PE/PS EPO |

|---|---|---|---|---|

| 气泡构造 Bubble Structure |

独立 Independent |

独立 Independent |

独立 Independent |

独立 Independent |

| 机械强度 Mechanical Strength |

最强 Strongest |

强 Strong |

强 Strong |

强 Strong |

| 最高使用温度 Max Usage Temperature |

130℃ | 85℃ | 80℃ | 80℃ |

| 耐冲击性 Impact Resistance |

最佳 Best |

佳 Good |

差 Poor |

略差 Slightly Poor |

| 耐油耐温性 Oil and Temperature Resistance |

最佳 Best |

最佳 Best |

差 Poor |

略差 Slightly Poor |

| 吸水性 Water Absorption |

最小 Smallest |

小 Small |

小 Small |

小 Small |

| 吸水性 Water Absorption |

最小 Smallest |

小 Small |

大 Big |

大 Big |

| 项目 Project |

试验方法 Test Method |

单位 Unit |

主要产品体系 Main Products System |

||||

|---|---|---|---|---|---|---|---|

| 密度 Density |

ISO 845 | g/cm3 | 15P | 18P | 30P | 45P | |

| 0.06 | 0.05 | 0.03 | 0.02 | ||||

| 抗压强度 Compression Strength |

10% | ISO 1926 | MPa | 0.3 | 0.18 | 0.07 | 0.04 |

| 25% | 0.4 | 0.22 | 0.11 | 0.07 | |||

| 50% | 0.53 | 0.35 | 0.16 | 0.13 | |||

| 拉伸性能 Tensile Properties |

强度 Strength |

ISO 844 | MPa | 0.75 | 0.68 | 0.41 | 0.28 |

| 断裂伸长率 Breaking Elongation |

% | 18% | 18% | 17% | 16% | ||

| 撕裂强度 Tear Strength |

ASTM D3575 | KN/m | 3.47 | 2.93 | 2.47 | 1.9 | |

| 导热系数 Thermal Conductivity |

GB/T10294 | W/m•k | 0.038 | 0.038 | 0.036 | 0.035 | |

| 抗性化学试剂 Resistance Chemical Reagent |

1H Exposed | / | 表面无变化 No Changes in Surface |

||||

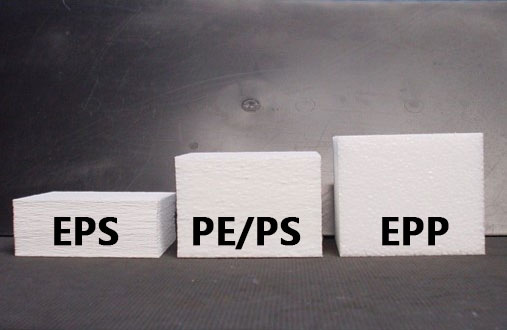

| 样品名称 Sample Name |

初始 Before |

30分钟后.第一次撞击 After 30min |

30分钟后.第二次撞击 After 30min |

30分钟后.第三次撞击 After 30min |

90分钟后.第三次撞击 After 90min |

|---|---|---|---|---|---|

| EPP 30g/L | 100.3 | 98.4 | 97.6 | 97.1 | 97.2 |

| PE/PS 30g/L | 100.4 | 87.3 | 84.6 | 83.1 | 83.4 |

| EPS 30g/L | 100.2 | 74.0 | 57.2 | 45.7 | 45.9 |

| 测试条件 Test Conditions |

测试项目 Test Project |

测试结果 Test Result |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 拉伸强度 Tensile Strength |

|

常态 Normal |

571KPa | ||||||||

| 老化 Ageing |

575KPa | ||||||||||

| 变化率 Change Rate |

+0.7% | ||||||||||

(1)90℃,4h → 室温,0.5h

(2)90℃,0.5h→ 室温,0.5h

(3)90℃,4h→室温,0.5h →-40℃,1.5h→室温,0.5h→70℃,95%RH,3h→ -40℃,1.5h→室温,0.5h

(1)90℃,4h → Room Temperature,0.5h

(2)90℃,0.5h→ Room Temperature,0.5h

(3)90℃,4h→Room Temperature,0.5h →-40℃,1.5h→Room Temperature,0.5h→70℃,95%RH,3h→ -40℃,1.5h→Room Temperature,0.5h

| 测试项目 Test Project |

测试结果 Test Result |

结论 Tconclusion |

|

|---|---|---|---|

| 尺寸变化率(1) Size Change Rate |

横 Horizontal |

0.14% | 无显著变化 No Significant Changes |

| 竖 Vertical |

0.31% | ||

| 厚度 Thickness |

1.51% | ||

| 尺寸变化率(2) Size Change Rate |

横 Horizontal |

0.12% | 无显著变化 No Significant Changes |

| 竖 Vertical |

0.21% | ||

| 厚度 Thickness |

0.35% | ||

| 尺寸变化率(3) Size Change Rate |

横 Horizontal |

-0.44% | 无显著变化 No Significant Changes |

| 竖 Vertical |

-0.41% | ||

| 厚度 Thickness |

1.28% | ||

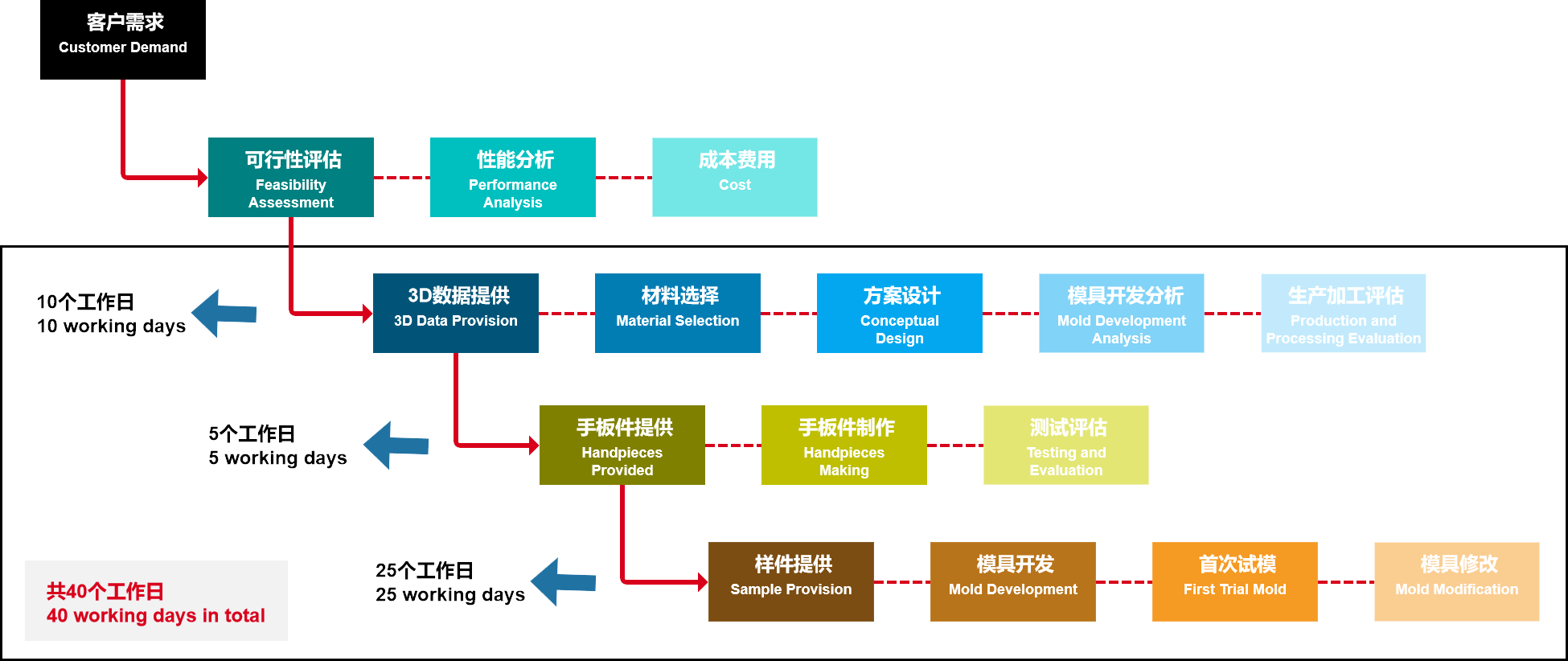

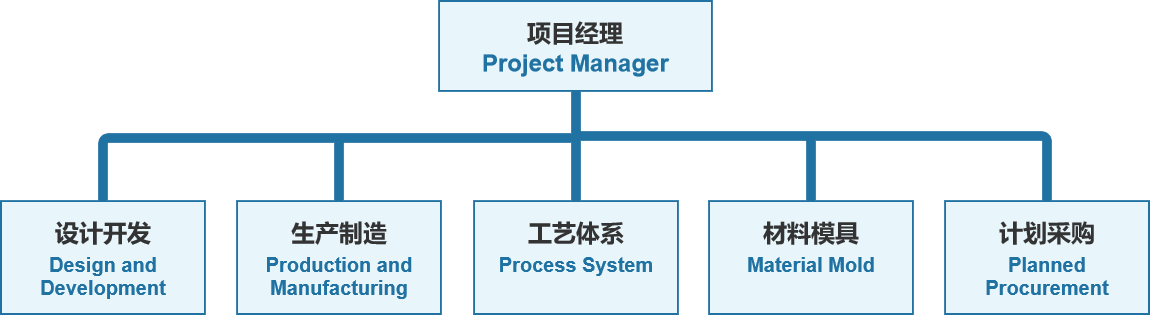

Project management system

Development and Implementation Progress